If you’ve ever been under the hood of a car and heard that distinctive squeal, then you know it’s probably time to replace your serpentine belt. Doing so might seem intimidating, but don’t worry. I’ll help you learn how to put a serpentine belt on. And even if you’ve never attempted this task before, with my step-by-step guide, you’ll see how the whole process can be straightforward. So, let’s get started.

To put a serpentine belt on, first, identify the correct routing of the new one. Locate the belt tensioner pulley and use a tool to rotate it counterclockwise to release the tension on the old one. Remove the old belt and carefully route the new one, then release the tensioner to apply pressure. Check that the belt is properly seated on all pulleys, start the engine to observe the strap for a few minutes, and adjust the tension if necessary.

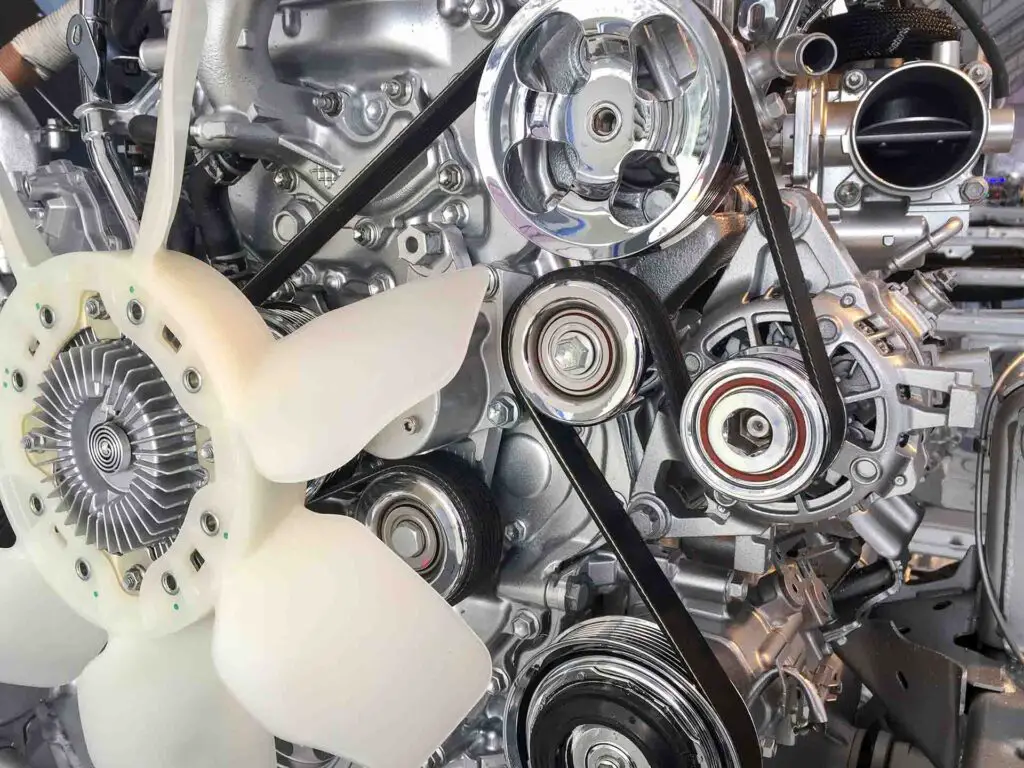

What Is a Serpentine Belt?

Maybe you’re not familiar with it, but ages ago, vehicles didn’t have a serpentine belt but a V-belt. With the evolution of cars in recent years, many vehicles have switched to using serpentine belts instead of V-belts. These are wider and flatter than V-belts, and they can drive more accessories with a single strap. They are also less prone to slipping and require less maintenance.

A serpentine belt is a single, long, continuous strap that drives multiple engine components in a vehicle. It is usually made of a durable rubber material and is ribbed on one side to grip the pulleys. It is responsible for driving the engine’s alternator, power steering pump, air conditioning compressor, water pump, and other components.

Why Is Important for It to Be In Perfect Condition

The serpentine belt needs to be in perfect condition because it plays a critical role in the operation of the engine components that it drives. If it is worn, damaged, or improperly tensioned, it can slip or break, causing the engine to lose power, overheat, or even fail. A broken one can also lead to other problems, such as loss of power steering, air conditioning, and electrical power, which can be a safety hazard while driving.

Regular inspection and replacement of the serpentine belt surely are some of the drivers’ responsibilities. It can also prevent costly repairs and unexpected car expenses. Therefore, it is important to keep it in perfect condition to maintain your vehicle’s safety, reliability, and performance.

Step 1: Gather the Necessary Tools and Materials

Use quality components, including a reputable brand of serpentine belt, to ensure proper fit, function, and longevity. Inferior quality belts can wear faster, crack, or slip off, causing damage to other engine components or the strap itself. Using high-quality components can also prevent costly breakdowns and repairs.

So, before starting the process, gather the following tools and materials:

- The new serpentine belt,

- Breaker bar or ratchet wrench with appropriate size socket or tensioner tool,

- Work gloves,

- Safety glasses.

Step 2: Identify the Belt Routing Diagram

Identifying the correct routing of the new strap can be done by locating the routing diagram, which is usually located on a sticker under the hood or in the owner’s manual. The routing diagram shows the path around the various pulleys, including the alternator, power steering pump, air conditioning compressor, and water pump.

Following the correct routing diagram, you’ll know how to put a serpentine belt back on and ensure the components are installed properly and function correctly. If the routing diagram is missing or illegible, take a clear photo of the old serpentine belt before removing it. This will serve as a reference for installing the new one in the correct routing.

Step 3: Loosen Tensioner Pulley

The tensioner pulley is designed to automatically adjust the tension on the serpentine belt to compensate for wear or stretch over time. It uses a spring-loaded arm to apply pressure to the band, keeping it tight and preventing slipping.

You must release the tensioner pulley to allow the band to be removed and the new one to be installed. This can be done using a breaker bar or ratchet wrench to rotate the tensioner pulley counterclockwise. This will release the tension on the old strap, allowing it to be removed.

How to Loosen the Tensioner Pulley?

Before installing a new strap, you need to release the tension on the old belt by loosening the tensioner pulley. So, make sure you locate the tensioner pulley, which is usually near the top of the engine and has a square hole or a bolt head in the center. Then, insert a breaker bar or ratchet wrench with the appropriate size socket or a tensioner tool into the square hole or bolt head of the tensioner pulley.

Rotate the tensioner pulley counterclockwise to release the tension. While holding the tensioner pulley in the released position, carefully remove the strap from the pulleys. Make sure to wear safety glasses and work gloves during this process.

Step 4: Remove the Old Belt

The old band may have become worn or damaged over time, causing it to slip or break, leading to poor engine performance or even engine damage. Removing the old one also allows for proper inspection of the belt and pulleys for any signs of wear or damage.

How to Remove the Old Serpentine Belt?

The process is the same for all cars, whether you have the most expensive vehicles or not. Here is a guide on how to remove the old serpentine belt:

- Locate the strap on your engine. It will wrap around several pulleys, including the crankshaft pulley, alternator, power steering pump, air conditioning compressor, and water pump.

- Using a breaker bar or ratchet wrench with the appropriate size socket or a tensioner tool, loosen the tensioner pulley by rotating it counterclockwise. This will release the tension on the old strap.

- Carefully lift the old serpentine belt off of the pulleys, taking note of its routing. You may want to take a picture or draw a diagram of the belt’s routing to help install the new one.

Tips for Safely Handling the Old Belt

Taking all the needed precautions surely will keep you safe and provide the best care for your four-wheeler. This being said, here are some tips for safely handling the old serpentine belt:

- Wear gloves to protect your hands from dirt, grease, and sharp edges on the band.

- Do not touch your face or clothing with gloves while handling the old strap to avoid transferring dirt and grease.

- Keep the old belt away from your eyes and face to avoid injury.

- Do not bend or twist the old strap excessively, as this can cause it to crack or break.

- Dispose of the old one properly. Check with your local recycling center or auto parts store for guidelines on how to dispose of the old band.

- Always inspect the old strap for signs of wear or damage before removing it. If it appears worn or damaged, it is recommended to replace it.

Step 5: Install New Belt

Installing a new one correctly is essential for the reliable and efficient operation of the engine’s components. No matter if you have a car for the city or one for off-road driving. So, let’s check how to do it.

Tips for Selecting the Right Replacement

Begin with choosing the suitable component. If you’ve never done it before, here are some tips for selecting the right replacement serpentine belt:

- Check your vehicle’s owner’s manual for the correct specifications of the belt, including its length, width, and number of ribs.

- Use a reputable brand that meets or exceeds the specifications recommended by the manufacturer.

- Avoid purchasing a used one or a strap that is not specifically designed for your vehicle.

- Choose a belt that is compatible with the other components of your engine, such as the alternator, power steering pump, air conditioning compressor, and water pump.

- Consider the climate and driving conditions where you will be using your vehicle. For example, if you live in a hot climate or do a lot of towing, you may want to choose a band that is designed for high temperatures and heavy loads.

How to Install the New Serpentine Belt Correctly?

You should first locate the diagram of the belt routing in the engine compartment or the owner’s manual. Next, find the tensioner pulley and loosen the bolt holding it in place. Then, use a socket wrench to turn the tensioner pulley to release the tension on the belt. Remove the old one and compare its size and shape with the new one to ensure they are the same.

Starting from the bottom, wrap the new belt around the pulleys according to the routing diagram. Make sure it is properly seated on each pulley. Use the socket wrench to turn the tensioner pulley again, allowing the strap to slip onto the last pulley. Finally, double-check the belt’s alignment and tension. The band should be snug but not too tight or loose.

Note I’ve come across many questions like this: “How to put on a serpentine belt without a tensioner?” Without a tensioner, the strap is likely to slip, causing damage to the engine and accessories. So, I wouldn’t recommend it.

Step 6: Check Belt Tension

Checking the tension is crucial to ensure the strap functions correctly and lasts a long time. If the band is too loose, it may slip off the pulleys, causing the engine to overheat or the alternator to fail. On the other hand, if the strap is too tight, it can cause premature wear on pulleys and bearings.

To check the tension, you can use a tension gauge (I have and use a Buachois gauge). Place the gauge on the belt’s longest span, typically between the alternator and crankshaft pulleys. Press the gauge against the belt with moderate force and read the tension value on the gauge.

Step 7: Test the New Serpentine Belt

To test the new setup, start the engine and observe the belt while it’s in motion. Check for any signs of slippage, misalignment, or noise. The strap should run smoothly without any squealing or chirping sounds. If you notice any issues, turn off the engine immediately and inspect the belt’s alignment and tension.

Learn How to Tinker, and Your Car Will Have a Smooth Ride

Whether it’s your daily commute, a cross-country road trip, or just around town, having the knowledge and skills to understand how cars work can be an invaluable tool. Through careful tinkering, you’ll not only enhance your car’s performance and reliability but also gain the satisfaction that comes with working on your vehicle. With a little bit of research and practice, anyone can learn how to tinker with their car and keep it running smoothly.