A carburetor is necessary for cars because it serves multiple functions. From fuel consumption to efficiency, this component plays a crucial role in a vehicle. If you want to know more about these components, you should learn how to tune a carburetor, including how to tell all of its components apart. Luckily, it’s not that hard.

What Is a Carburetor?

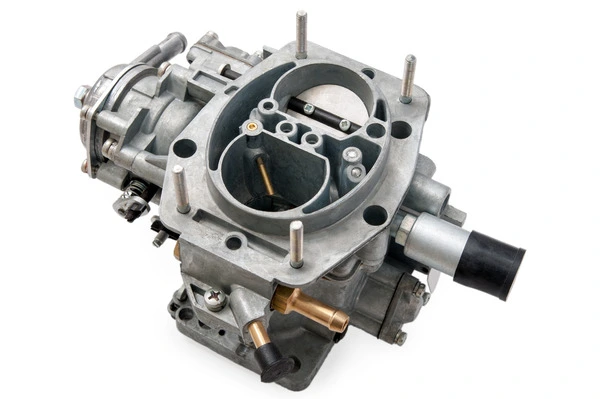

Before learning how to tune a carburetor, you need to know all about this component. A carburetor is responsible for distributing and mixing air and fuel within the internal combustion engine. Essentially, it’s meant to mix air and fuel equally.

Every carburetor maintains a specific air and fuel mixture ratio at all times, making it possible for other components to work together. This mix of fuel and air is called a “combustible mixture.” Besides the mixture regulation, the carburetor is in charge of controlling the engine speed.

The car has a throttle, which controls the valve that lets in the combustible mixture into the engine. The harder the throttle is pressed, the valve is more open, and more mixture comes in. When you keep your engine idle, the throttle isn’t fully open, and not a lot of mixture comes through.

There are three types of carburetors in circulation: 1-barrel, 2-barrel, and 4-barrel carburetors. Which one you’ll have in your car will depend on the type of engine; there can even be multiple carburetors in a car if there’s a high-performance engine installed.

Where Is It Located?

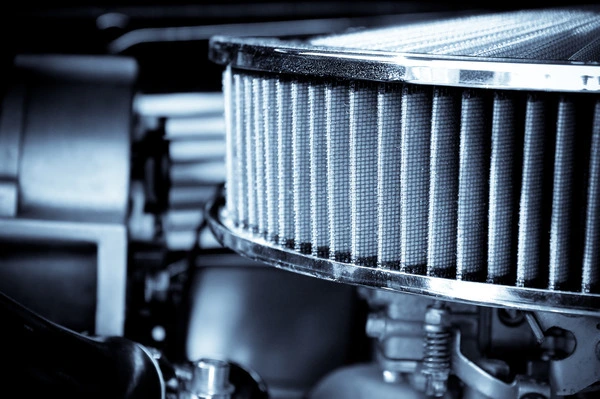

The carburetor sits on top of the engine but beneath the air filter. It’s attached to the throttle cable (hence the valve control,) which is connected to the gas pedal. Because of its connection to many other components that keep the engine running smoothly and safely, it’s considered to be the heart of the engine.

Rich vs Lean Carburetors

A normally functioning carburetor shouldn’t be rich or lean. These are issues with over and under-functioning that also affect the engine performance, fuel consumption, and efficiency. Here’s what it means when you have a rich and lean carburetor.

- Rich – this problem occurs when there’s too much gasoline in the necessary air and fuel mixture; this can be caused by dirty fuel injectors which get stuck in the open position. When that happens, gas pours into the carburetor and overflows it and the combustion chamber with fuel,

- Lean – this is when your air/fuel mixture is overly packed with air rather than gasoline; similarly this is caused by dirty or stuck fuel injectors, but also a clogged fuel filter and several dying sensors. Essentially, the engine is fuel starved when the carburetor is lean.

What Are the Carburetor’s Main Components?

Carburetors have several working parts crucial for their functioning. Considering they mix fuel and air, their components need to be separate and specialize in what they do best; besides, these components all need to function together as much as they do separately.

The main components usually include a liquid fuel storage chamber, an idling jet, the main jet, a choke, an accelerator pump, and a venturi-shaped air flow restriction.

The fuel is located in the storage chamber; the choke is a type of butterfly valve that reduces the air influx and draws fuel charges into the cylinder. The idle jet is there for the fuel to flow out, and the main jet activates when the throttle valve is fully open.

Finally, the venturi-shaped restriction limits air flow and reduces the pressure when fuel is drawn from the main jet. This maintains the air and fuel levels equal, keeping the balance constant.

Methods for Carburetor Tuning

Tuning the carburetor seems more complex than checking a car thermostat or replacing bad spark plugs, but it’s not. It’s safer than some things you could be attempting to do on your own, starting with disposing of a car battery.

You wouldn’t need much to tune the carburetor, but you need to know the methods necessary to make the tuning possible. Some things you should be aware of before starting a tune-up are that the engine needs to warm up to a normal operating temperature and to listen for unusual noises.

Adjusting the Mixture of Air and Fuel

This type of tuning is done on most vehicles. Here, you need to locate the air filter and remove it, while the car is off, of course. You’d only let the engine run so it could warm up; this will show you what you’re looking for and help you determine whether you have a lean or rich carburetor.

Here, you’d open the hood, locate the air filter, and remove the entire assembly. To remove the air filter, you must unscrew the wing nut and everything else that’s connecting it to the rest of the rig. In most cars, the air filter is attached to the carburetor directly.

You can also look for the adjustment screws at the front of the carburetor; there are two, and they control the air and fuel flows. They typically look like flathead screws, meaning you can use screwdrivers to turn and adjust them.

Now, if you start the car while checking the adjustment screws, you can listen for some unusual noises or engage your sense of smell. A lean carburetor will ping at higher RPMs – that means you need more gas. A rich carburetor won’t make noise, but it will emit a strong gas smell – that means you should bring down the gas.

After regulating the screws, you should consider replacing the air filter assembly.

Adjusting the Idle Speed

This method may be a bit more complex, as you need to use your manufacturer’s manual for this; that’s because locating the idle mixture screw can be tough, and it is possible to mix up with the idle speed screw.

The idle mixture screw is there to limit the fuel flow when the engine is idle. Again, warm up your car to a normal operating temperature. Try turning the screw clockwise a bit and listening to the engine. Give it about 30 seconds to respond to the adjustments and turn it slowly, as even the most minor clockwise turn can help tune the carburetor.

Replacing the air filter is also recommended after doing this. These methods aren’t complex and don’t require any knowledge of checking the clutch master cylinder or the brawn for replacing a flat tire.

The Right Tuning Tools

As mentioned before, you don’t need too many tools to tune the carburetor. Since most of the stuff you’ll be doing is unscrewing some tight screws, the effort will likely be minimal. Still, if you can manage with some more advanced tools, you can try to use them.

What you’ll need is:

- A screwdriver (flathead, preferably, but if you have a flathead and a six-head screwdriver, get both),

- An optional vacuum gauge,

- An optional AFR (wideband) gauge.

How to Tune a Carburetor With Extra Tools

Whether you simply use a screwdriver or try to impress no one in particular by also using a vacuum gauge, the steps for tuning a carburetor are fairly easy. Prepare your tools, and my advice is to ask another person to help you when listening to the changes in the engine.

Your ears may be too well adjusted to the noise, so that they don’t recognize changes happening. Try to do the tuning in a safe and familiar place, too; this will make you more comfortable around the car and give you more space for the tools.

Remove the Air Filter and Warm Up the Engine

In the methods previously explained, if you decide to tune your carburetor by adjusting the air and fuel screws or the idle mixture screw, you’ll have to remove the air filter when doing either.

The air filter assembly can come in a panel, circular, or cylindrical shape. They’re made of pleated materials that filter the air, such as cotton, synthetic paper, or foam. This assembly helps prevent abrasive particles from entering the engine through the airflow.

Unscrew the wing-nut and additional components connecting the air filter to the carburetor, and remove the air filter. While you’re there, locate the idle speed and idle mixture screws.

Hook Up the Vacuum Gauge and Set a Baseline

Hooking up the vacuum gauge to the carburetor isn’t too difficult. However, you do need to know what and where the manifold vacuum port is. That’s where the vacuum gauge connects.

The manifold vacuum is at the base of the carburetor, and it has a standard PCV port. You’ll notice this port when comparing the vacuum gauge attachment size with the port size. Vacuum gauges were made for this purpose, so yours will also fit where it’s meant to. Check the base of the carburetor for the port.

When you’ve hooked the vacuum gauge, it’s time to set a baseline, which is the fancy vocabulary for setting the carburetor back to its factory setting. This is normally done by turning the idle mixture screw one and a half to two turns outward and by turning the idle speed screw with one to one and a half inward turn.

How to Observe the Vacuum Gauge

While adjusting the air/fuel mixture screws (or the idle screws), you should observe the vacuum gauge. When the engine gets rougher, the vacuum will drop; oppositely, when the speed smooths out, the vacuum will increase.

When the engine speed smooths and the vacuum drops, you should continue to adjust the screws to the peak engine speed (compared to the factory settings).

Tips for a Successful Carburetor Tuning

There are several other tips to check out when tuning your carburetor. If it seems impossible, based on the instructions so far, you can always apply more methods and tips for regulation. Here are some of the tips for making your tune-up a bit more successful:

- Ensure that your ignition timing is right. more modern engines and vehicles require more advanced timing when idle so you can add a few more degrees on the screws when tuning,

- It’s not necessary to revert to factory settings, but it’s very helpful in determining where your engine and carburetor are in terms of running conditions. This can be especially useful if you don’t know your car’s factory settings,

- Even brand-new carburetors need tuning once in a while, so don’t think it’s unnecessary if you’ve recently purchased your four-wheeler,

- Carburetor tuning could and should be a frequent occurrence. If you do it with a professional mechanic the first time and observe their methods, you can apply it with every next check,

- If your idle speed screw needs more than two turns to get adjusted, the issue is likely bigger. Perhaps the carburetor needs a deep cleaning or more advanced tuning steps.

If You’re Unsure of the Right Steps, Go to a Mechanic

OK, I lied to you a little bit. Tuning a carburetor is a bit more complicated than expected, but that’s because it requires a special touch. Truthfully, the more you drive your car, the more you’ll know about it – from the kinds of noise it makes to when it runs smoothly and when some stuff feels off.

Still, even if you’ve been driving for years, you may not feel as skilled in testing and tuning car components on a professional level. For this, the best method is to call a mechanic or someone you know who is good with cars. This will ensure you have the best service possible for your car.